We celebrate our most recent project in collaboration with the valued Quirónsalud group

In our constant pursuit of excellence in the hospital sector, we recognize Quirónsalud as an essential strategic partner. We strive continuously to stay at the forefront as manufacturers of hospital equipment, and therefore deeply value our collaboration with a prestigious reference like the Quirónsalud Group.

Day by day, we work to enhance our technology and provide innovative solutions that meet the changing needs of the hospital environment. Hence, we are delighted to share our recent achievement: the successful implementation of our hospital equipment products at the Quirónsalud Valle del Henares Hospital.

This collaboration not only marks a significant milestone in our journey but also reflects our shared commitment to providing the best possible medical care to our patients.

“At Quirónsalud Valle del Henares Hospital, we are committed to providing the highest level of care. Thanks to its modern facilities combined with processes based on the extensive experience and shared knowledge of the Quirónsalud group, the safety and well-being of both patients and all medical staff are ensured.”

This hospital is a benchmark of innovation and technology in the field of healthcare. That’s why they have embraced innovation and technology with Tedisel Medical. Their diverse facilities include:

- Primary medical and surgical specialties.

- 50 consultation rooms.

- 66 individual exterior rooms.

- 6 adult Intensive Care Unit beds.

- 7 neonatal Intensive Care Unit beds.

- 7 operating rooms.

- 3 Labor and Delivery Units.

- Outpatient area.

- Imaging diagnostic area with MRI, CT scan, mammography with tomosynthesis, etc.

- General, pediatric, and gynecological emergency services available 24 hours a day.

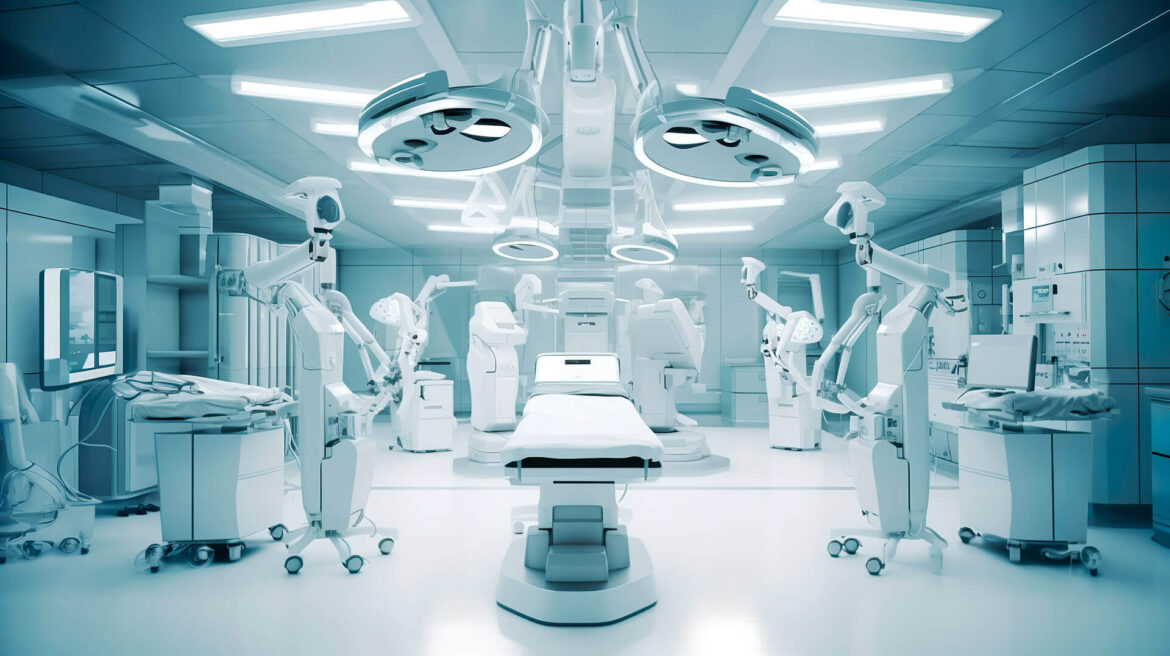

Hospital Architecture and Innovation in Healthcare

Quirónsalud Valle del Henares Hospital has been conceived with the idea of achieving maximum efficiency, improving the care process, and optimizing the patient experience.

“It is a project where the humanization of spaces and the pursuit of user well-being are favored.”

Our product line has been a source of innovation in the 14,081 m2 building, which includes a total of 66 individual rooms, 6 adult ICUs, 7 neonatal ICUs, 7 operating rooms, 50 consultations, labor and delivery units, outpatient, and emergency areas, covering all levels of care, from basic to more complex.

At Quirónsalud Valle del Henares Hospital, where specialization in women’s health and care during pregnancy, especially during the crucial moment of childbirth, is a priority, Tedisel Medical takes pride in offering cutting-edge solutions for Neonatal Intensive Care Units, with our ceiling suspension system, ATLAS. This model adapts to the specific needs of each project, thus guaranteeing optimal care for newborns. The versatility of ATLAS allows for maximum focus and centralization of controls, creating an efficient working environment for both medical staff and patients.

We back technologically advanced operating rooms, hence, we offered our QPANEL Technical Panel model to provide an agile and efficient working environment. Equipped with two screens and a Windows PC, along with accessories like digital timers and keyboards, the QPANEL proves to be the optimal choice for outfitting operating rooms. Its Corian® surface and adaptability in size and components allow for optimal focus and centralization of controls.

The building’s design focuses on achieving a high level of energy efficiency by incorporating both active and passive components for energy conservation. The development of healthcare spaces transcends their mere and essential functionality. It aims to address the creation of these spaces from the perspective established by the theory of Salutogenesis: designing welcoming environments that empower patients and users to maintain control over their well-being.

It is for this reason that Tedisel Medical offered our headboards to fit the objective of the project: to help the patient to feel as good as possible from the moment he/she enters the hospital. Our range of headboards was adapted to the project providing customized solutions and improved design alternatives to facilitate the work of health professionals and the patient. We installed two models: the N270 and the AIS. The N270 monobloc bed had unit was perfectly integrated in the Pediatric Emergency rooms, offering an efficient and aesthetically appealing solution, while our AIS design model was installed in all the hospitalization rooms, providing an architectural touch with its HPL finish.

Commitment to Continuous Improvement

Our solutions have contributed to improving the efficiency of the hospital team, simplifying workflows, and improving coordination among staff. In addition, the successful installation of our products ensures a high standard of care for all hospital patients, offering a more comfortable and secure experience during their stay.

In conclusion, our collaboration with Grupo Quirónsalud has been a significant step forward in our quest for excellence in the hospital sector. The successful integration of our solutions at Hospital Quirónsalud Valle del Henares reflects our ongoing commitment to innovation and constant advancement in healthcare. We are proud to have contributed to improving the efficiency of hospital equipment and raising the standard of care for all patients at the hospital. We will continue to work closely with Quirónsalud and other partners to further innovate and improve the patient experience.