Artificial Intelligence (AI) has almost completely transformed numerous areas within the healthcare sector, and the manufacturing of medical equipment is no exception.

With advances ranging from device design to the optimization of production processes, AI has driven a leap in the quality, efficiency, and personalization of healthcare technology in hospital equipment.

But what does the application of Artificial Intelligence in the manufacturing of medical equipment actually entail?

Optimized device design

AI helps design medical devices with unprecedented precision. Machine learning tools can analyze vast amounts of clinical and biomechanical data to create customized designs tailored to the specific needs of patients.

For example, algorithms can identify patterns in medical imaging data, such as X-rays or CT scans, to generate prosthetics that accurately replicate a patient’s anatomy.

Additionally, AI can predict device performance prior to manufacturing through virtual simulations.

Additive manufacturing, personalization, and automated processes

Additive manufacturing, such as 3D printing, has clearly benefited from AI. Printing parameters like temperature, speed, and materials are optimized to ensure consistent, high-quality results.

AI also revolutionizes production lines through intelligent automation. AI-guided robots are capable of assembling medical devices with micrometric precision, minimizing the likelihood of human errors.

Moreover, AI-based systems can predict the maintenance needs of production machinery by analyzing real-time data and using machine learning models to detect wear before it becomes a critical issue.

Benefits of AI in medical equipment manufacturing

AI enhances efficiency by optimizing every stage of manufacturing, from design to production and distribution. This results in lower costs and reduced time to market for new medical devices.

“Ability of artificial intellegence to accurately analyze data helps identify product defects long before they reach the market, enabling manufacturers to deliver customized medical devices at scale.“

Practical examples in the healthcare industry

Some noteworthy advancements include surgical robots performing procedures with remarkable precision, wearable devices for cardiovascular health monitoring, and smart glucose meters that aid in managing chronic conditions like diabetes.

Other innovative technologies include digital twins, which simulate treatments based on personalized data, and sleep tracking devices that improve rest and recovery for patients and athletes.

Challenges of AI in healthcare

Of course, it’s not all smooth sailing.

There are several challenges to address. For starters, the manufacturing of medical devices is highly regulated, and incorporating AI adds an extra layer of complexity. Manufacturers must demonstrate that their AI-based systems are safe, effective, and compliant with applicable regulations.

Furthermore, AI relies on large volumes of data to function well, raising concerns about patient information privacy and security. In addition to strict measures to protect this data, there’s the challenge of integrating AI with existing systems, which is not always straightforward.

Finally, there is a reliance on specialized talent, which can be difficult to recruit or find.

The future of the AI & medical equipment tandem

With the momentum of AI technology, its impact on hospital equipment is set to grow significantly in the short and medium term.

Emerging trends influenced by AI include:

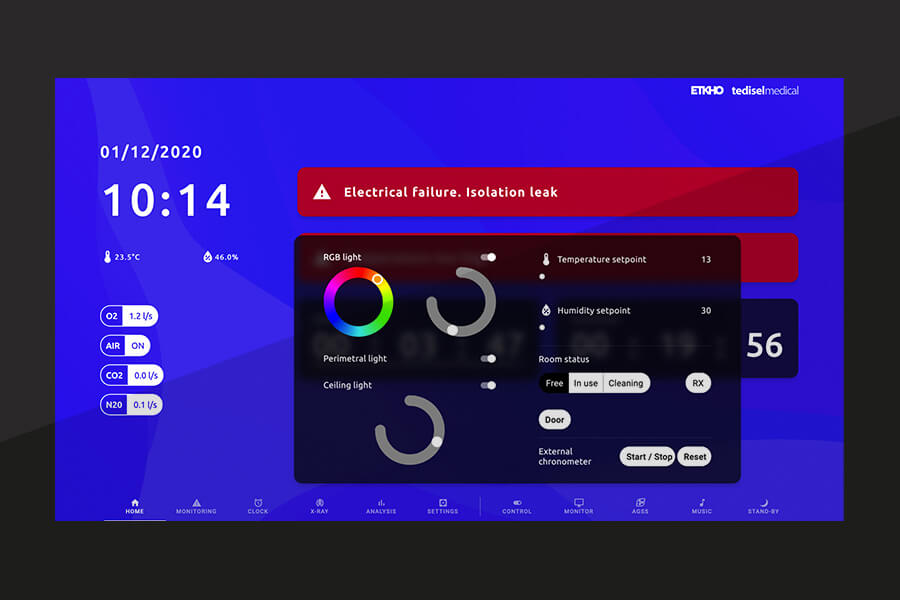

Smart and connected devices

The integration of sensors and machine learning capabilities in medical devices will enable real-time patient health monitoring and automatic adjustments of device performance.

Enhanced simulation

AI-based models will simulate real-world conditions with greater accuracy, improving device design and validation.

“Artificial intelligence has permanently transformed the landscape of medical equipment manufacturing, enhancing the efficiency, quality, and personalization of devices.